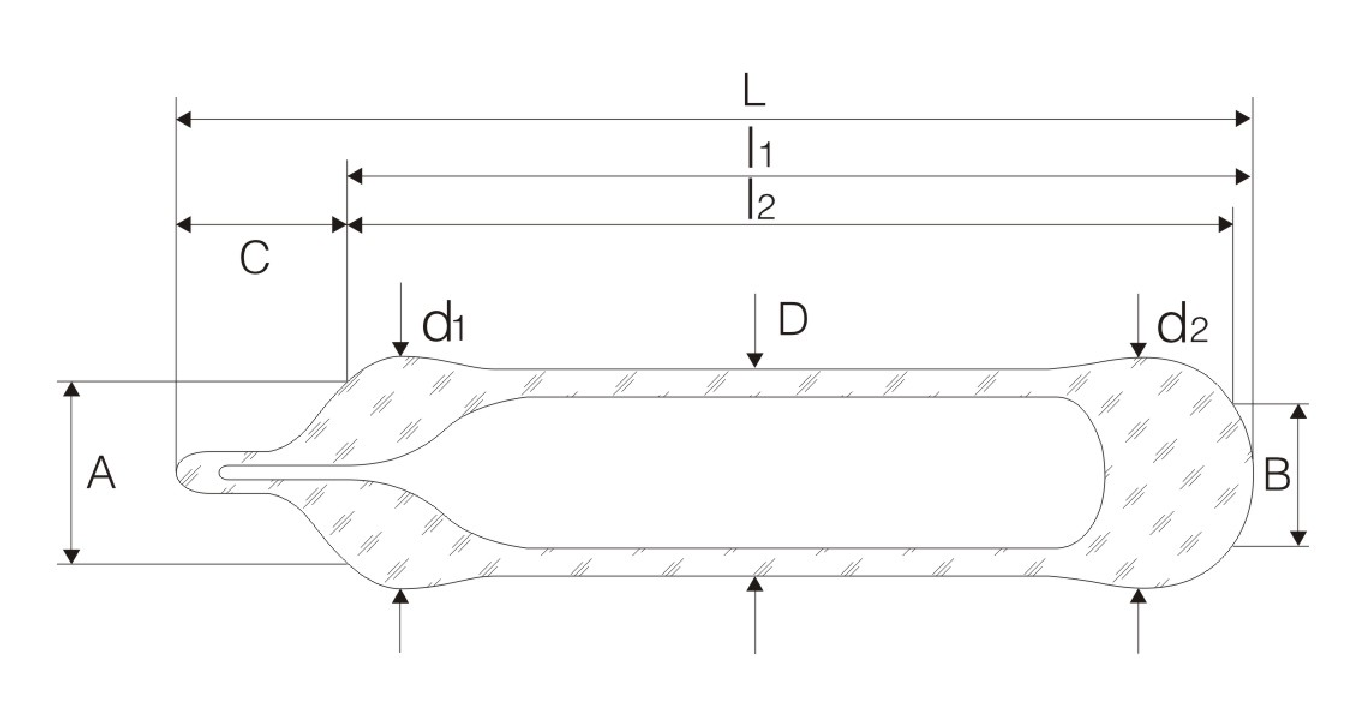

| Size(mm) | Temperature Rating(℃/°F) | Color | |

| A | 3.8 | 57℃ / 135°F | orange |

| B | 2.02 | 68℃ / 155°F | red |

| C | <4.5 | 79℃ / 175°F | yellow |

| D | 5±0.1 | 93℃ / 200°F | green |

| d1 | 5.3±0.2 | 141℃ / 286°F | blue |

| d2 | 5.3±0.3 | ||

| L | 24.5±0.5 | ||

| l1 | 20±0.4 | ||

| l2 | 19.8±0.4 | ||

| Glass bulb load(N) | Average Cursh load(X) | 4000 | |

| lower Tolerance Limit(TL) | ≥2000 | ||

| Maximum clamping torque | 8.0 N·cm | ||

| Response time index(m*s)0.5 | 80<RTI≤350 | ||

All sprinkler bulbs will be inspected when leaving the factory, including:

1. Appearance and size Ensure that the outer surface of all sprinkler bulbs is not damaged, there are no bubbles or other impurities inside the glass material, and the bubble size in the working liquid of sprinkler bulbs of the same specification is uniform. The dimensional deviation of all sprinkler bulbs is within the specified allowable range. The temperature and color of all sprinkler bulbs are easy to identify. 2. Static operating temperature The static operating temperature of all sprinkler bulbs shall not exceed the following temperature range: X ± (0.035x + 0.62) x refers to the nominal operating temperature, and the unit is Celsius (℃) 3. Crushing load The average crushing load shall not be lower than the specified value, and the lower limit of crushing load error shall not be lower than 50% of the average crushing load. My company's main fire products are: sprinkler head, spray head, water curtain sprinkler head, foam sprinkler head, early suppression quick response sprinkler head, quick response sprinkler head, glass ball sprinkler head, hidden sprinkler head, fusible alloy sprinkler head, and so on. Support ODM/OEM customization, according to customer requirements.